43 Days: Start of Safety Data Sheet SDS Cleanup

Week 3, time to process Purchases and Inventory to Pounds and cleanup Safety Data Sheets…

(Note that since it’s 43 days and counting down, we’ll be viewing Safety Data Sheet cleanup in light of only those materials Inventoried and/or for which you had Receipts during the reporting year)

(I’ll be alternating Purchases/Inventory Processing and Safety Data Sheet cleanup until we’ve finished both processes)

In a perfect world, you would clean up the data for all of your Safety Data Sheets SDS’s during this cleanup process. Since we’re 43 days and counting down to Tier2 deadline, it’s probably wise to prioritize what you need most and work from there.

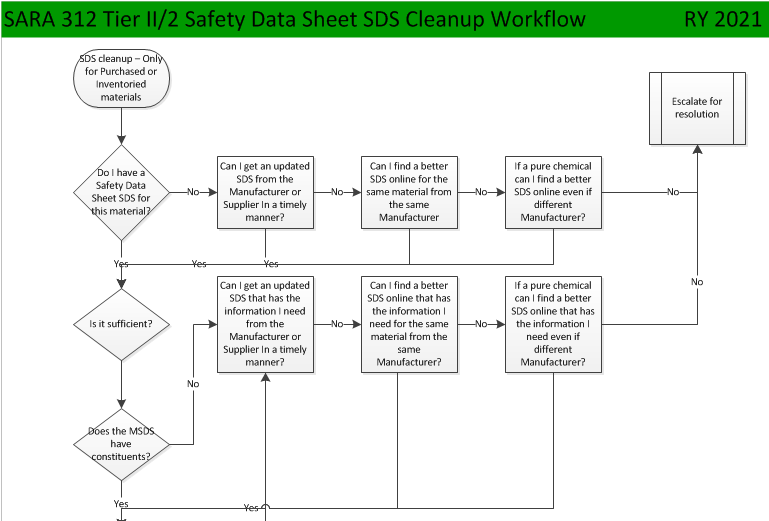

If the SDS is missing information, you may or may not be able to get a better Safety Data Sheet from the Manufacturer. If not, feel free to look to other sources. Sometimes an older SDS actually has better information.

Start of SDS cleanup: Do I have one and is it sufficient?

Again, prioritize your constituent cleanup around materials you have received or encountered during inventory. It is also useful to prioritize these descending by the total amount and with a second prioritization around Extremely Hazardous Substances EHS’s.

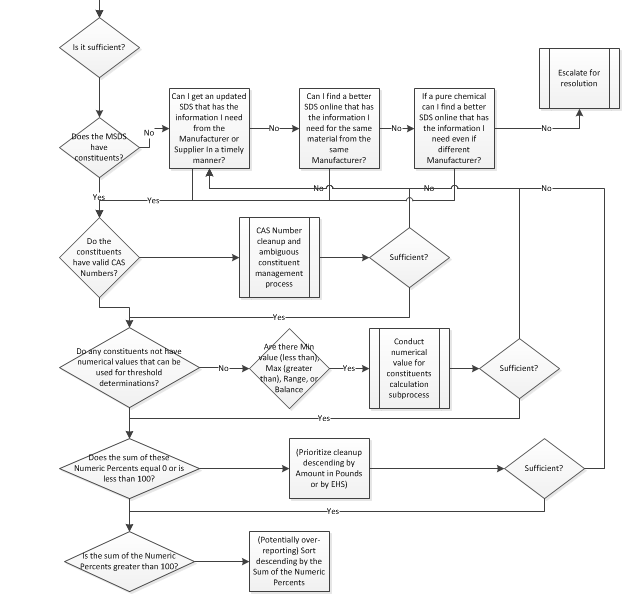

For constituents, you will want to clean up all the constituents for all the SDS’s you received or inventoried for the previous reporting year.

That will be the only way to insure that constituents that should have been reported, even if they originally had ambiguous or wrong CAS Numbers (e.g. “Additive” constituent name with no CAS Number provided, which might require research, compared to “Lead and/or Lead Oxide” with a CAS Number of “Multiple”, for which you probably want to research or assign at least the CAS Number for Lead), were included in threshold determinations.

Continuing SDS Cleanup-High level constituent cleanup

It’s not unusual for SDS’s to have the constituents entered as > (the greater than symbol), “Greater than”, (text), < (the less than symbol), “Less Than” (text), “Balance” or with a lower and upper constituent percentage range. We’ll do a separate blog post around those.

By adding up the Numeric Percents you will be using to conduct your threshold determinations, you can determine how much you might be missing and follow up to get a better SDS accordingly.

For example, in one case an etching solution only showed 0.6 percent Chromic Acid. The other 99.4% of the SDS constituents were totally missing. It turns out that the balance was Nitric Acid, which for this facility was reportable. Good to know and to find out ahead of report submission.

One last tiny plus is that by adding up the numeric percentages and displaying descending by the sum, you can identify materials for which you might be over-reporting. It was not uncommon for metals such as welding rods, where the SDS percentages were all “Greater than 1”, when you reached out to the manufacturer for better constituent percentages many of the ingredients were small than the “100 percent” you would have to use in the absence of better information.

Note that we’re not talking about getting Health Hazard information, we’ll come back and clean that up for only those materials that we determine to be reportable.

Note also that if you received the material in volumetric units of measure (gallons, pints, etc.) you will need a Specific Gravity value that you can multiply by to convert from the received/inventoried unit into pounds (“greater than 1” is not useful or usable). We’ll address that in the further discussion of processing Inventory and Receipts through to Pounds (the unit of measure for threshold determinations for Tier2).

There are also a few big cleanup steps in the SDS cleanup subprocesses shown above, we’ll go through those separately

More tomorrow, here’s to March 2nd!

Michigan EGLE links from first and second webinars of 2022 SARA 312 virtual training courses:

I’m keeping these links for awhile because they are so useful. I’ll post the session 3 recording info when it becomes available. You can sign on and listen even if you didn’t sign up for the webinar series.

RECORDING LINK FOR SESSION 2: Wed Jan 19, 2022.

Really good example on batteries. This is the “in the weeds” how to conduct your threshold determinations episode: https://attendee.gotowebinar.com/recording/4027906237723673347

I talked to Mike Young, one of the presenters, right after the first webinar. He said that it’s not unusual for them to take phone calls from people from other states (with the warning to confirm that your state doesn’t have differences in their requirements compared to Michigan).

RECORDING LINK FOR SESSION 1:

https://attendee.gotowebinar.com/recording/7957790593170499843

PRESENTATION: (I wasn’t able to attach a copy of the presentation, email the link below and they will send it to you)

SARA TITLE III – TIER II REPORTING WEBSITE: http://www.michigan.gov/sara

MICHIGAN FACILITIES’ GUIDE TO SARA TITLE III: https://www.michigan.gov/documents/deq/deq-oea-saraguidebook_509720_7.pdf

CONTACT INFORMATION:

Mike Young and Adam Pohl

517-284-7272

Michigan EGLE SARA 312 virtual training courses for Jan 2022

Community outreach: What have you found best for conducting Safety Data Sheet cleanup? How much time do you spend on it? And what percentage of your Tier2 effort is it?

#SARA312 #SARATierII #SARATier2 #EPCRA #EGLE #March1EPAReportDeadline #Tier2Training