At the start of the digital transformation…

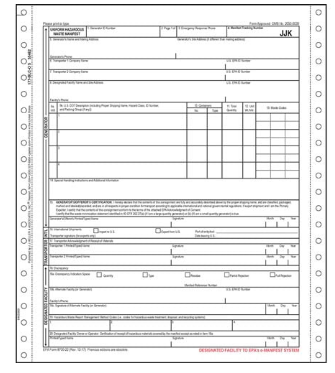

ManGuard was the first company to print Hazardous Waste Manifests

Before the e-manifest, even before the Uniform Hazardous Waste Manifest. Back when the forms were 7 part carbon paper forms and NOT pinfeed (you needed a printer that would friction feed the 7 part form, there were only a few of them). 27 state-specific forms, all totally different. We transitioned the forms to the Uniform Manifest forms when those came out (about the same number of non-uniform state manifest forms since states were allowed to customize some of the fields on the form, and were able to rearrange the size of the boxes for some of the fields).

The ap was used by particular facilities of Fortune 10 companies, and survived until EPA changed the form.

A story about usability, we installed the software at the Jeep plant in Toledo, OH, an automotive assembly plant that made the plant I started at look small. Probably 2 miles square and 5 stories high.

We didn’t hear anything from them after they attended training, which usually meant the software wasn’t being used. Then we got a call that they were upgrading from a 286 processor to a 386 processor (yes, that long ago).

I went down to move the software to the new machine, and was interrupted by a maintenance technician in greasy coveralls “Excuse me, I need to print a manifest”.

They had figured out that it was WAAAAY less work to fill out a manifest using the software (11 keystrokes) companred to hand-writing the information required through 7 copies (Waste Flammable Liquid, n.o.s (acetone, xylene), 3, PG III, D001)

A serious learning about what’s required for users to not only accept but embrace software…